Plant maintenance tends to be a key management issue for many pharmaceutical companies like yours. Consequently, proper maintenance management requires information about performance for the planning and controlling of maintenance processes. However, it is generally difficult to reconcile production and maintenance goals.

ERP software for plant maintenance is an absolute solution for your business to overcome the challenges.

Plant maintenance module is an integrated solution for your operational functioning. Essentially, it calculates the run time of machines and equipment and estimates their maintenance time and downtime.

We make it easier for you!

We have a process manufacturing solution for your business that can be integrated with SAP Business One. Furthermore, this exciting new development is packed with features to help keep your machine park running profitably and efficiently by giving them additional tools to:

- Minimize breakdowns,

- Keep assets in optimal working condition,

- Cut down on time lost due to equipment and machinery failures,

- Reduce maintenance costs,

- Improve maintenance accountability.

Better maintenance of machinery and equipment usually has knock-on effects in the form of improved product quality and overall productivity as well. Additionally, the degree of flexibility in Plant Maintenance is noteworthy. Furthermore, it accommodates a wide range of machine types and setups and is easy to adapt to every production environment.

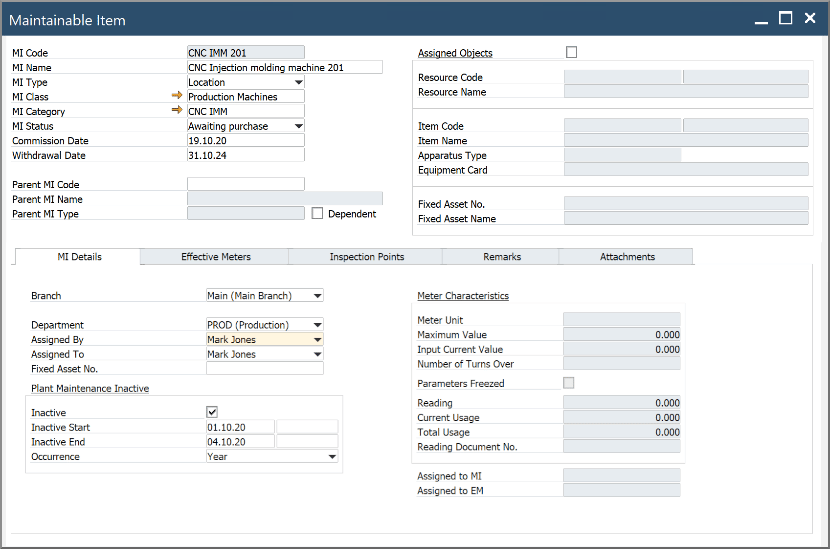

We use the concept of digital twins to create a Maintainable Item that represents a real machine, tool, or piece of equipment in the SAP Business One database.

What does the future hold for Plant Maintenance?

Well, there is a lot more to come. Basically, our Plant Maintenance comes in phases which can be broadly summarized as follows:

First Phase – Corrective/ Breakdown Maintenance and Planned/ Scheduled Maintenance.

Second Phase – Functionalities that support preventative and predictive maintenance, costing improvements, graphical and downtime in relation to Manufacturing Orders scheduling, and PDC inclusion.

Third Phase – Mobile application.

To integrate with a well-organized maintenance system, give us a call today!